- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

The latest five axis CNC machine tools

18/01/2021

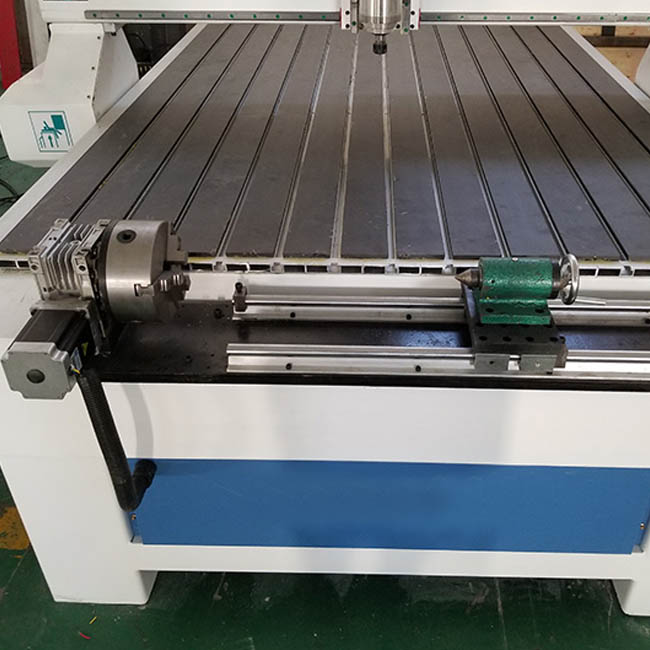

Entry Level Desktop 4th Axis CNC Router Machine with 2×3 Rotary Table

18/01/20214 Axis CNC Router 1325 with 4x8 Rotary Table

What is 4 axis CNC router?

The 4 axis CNC router is based on the common 3 axis CNC router. The fourth axis (A axis) is added to the rotation axis. In addition, the 4 axis CNC router machine is divided into four-axis three-linking and four-axis four-linking CNC machines, adding a rotating axis and the control system is also a four-axis linkage system to be called a true four-axis linkage CNC machine. Because of the rotary motion of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.If the 4 axis CNC router you purchased has only three feed axes (X, Y, Z), the Y axis can be manually replaced with a rotary axis, and only a maximum of three axes can be linked. This is a four-axis three-link CNC machine, which is also known as 4th axis CNC router.

If the 4 axis CNC router you purchased has four feed axes (X, Y, Z, A), it can be processed by four-axis linkage, and it can process planes, reliefs, cylinders, non-standard three-dimensional patterns, corner repair of 3D patterns, etc. .

Benefits of 4 Axis CNC Machining

The best 4 axis CNC router kit uses a DSP handle industrial control system. The four-axis linkage control has excellent and stable quality, good maintainability, and usability. It can control the completion of the 3D machining of the cylinder and the rotation of the tetrahedron. It is suitable for three-dimensional sculpture of figure statues and legs of European furniture. It has the following advantages:

1. The new four-axis linkage motion control method can be used offline, without additional computer.

2. Support A/C code format and special M code control.

3. I/O interface can be customized to provide users with a wide range of development platforms.

4. Intelligent processing memory function, support breakpoint continued carving.

5. Stronger anti-interference, passed multiple CE tests.

6. With parameter backup and parameter recovery functions, it effectively prevents the loss of important parameters.7. Machining of complex workpieces such as cylinders, prisms, and polyhedra.

Technical Parameters of 4 Axis CNC Router 1325 with 4x8 Rotary Table

| Brand | STYLECNC |

| Model | STM1325-R3 |

| Table Size | 4x8 |

| Working Area | 1300x2500x200mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Repositioning Accuracy | ±0.03mm |

| Table Surface | T-slot Table (Vacuum Working Table for Option) |

| Frame | Welded Structure |

| X/Y Structure | Helical rack, Taiwan HIWIN Rail Linear Bearings |

| Z Structure | Taiwan HIWIN Rail Linear Bearings and Ball Screw |

| Max Power Consumption | 3.2KW (Without Spindle) |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 3KW water cooling spindle (Italy HSD Spindle for Option) |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Lead shine |

| Working Voltage | AC380V/50/60Hz, 3PH (220V for Option) |

| Command Language | G Code |

| Operating System | DSP (Ncstudio/Mach3 for Option) |

| Computer Interface | USB |

| Collet | ER20 |

| X,Y Resolution | <0.01mm |

| 4 Axis CNC Router Software | Type3/Ucancam/Artcam |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Price Range | $5,380.00 - $10,180.00 |

Features of 4 Axis CNC Router 1325 with 4x8 Table Size

- 1. 1300*2500*200mm effective work area.

- 2. 300mm diameter rotary 4th axis.

- 3. 3KW water cooling spindle, 24000rpm.

- 4. 3.7KW Fuling inverter.

- 5. NK105 DSP controller.

- 6. Taiwan HIWIN #20 square linear guide.

- 7. Helical rack transmission for X, Y axis, powerful and stable.

- 8. Taiwan TBI ballscrew transmission for Z axis, most accurate precision.

- 9. T-slot working table.

- 10. Manual lubrication system.

- 11. Tool sensor calibration.

- 12. Japan OMRON limit switch.

- 13. The best cable, highly flexible, fire resistant.