What is Furniture CNC?

The Furniture Making Machine can quickly process raw materials according to different processing demand and efficiently complete the process of cutting, drilling, punching and other operations.

Blue Elephant provides a series of equipment for the furniture production line, including CNC cutting machine, automatic loading and unloading machine, vacuum press machine, edge banding machine, side hole drilling machine and other equipment to meet the individualized and diverse processing needs of furniture production. Mainly used in the cabinet wardrobe industry, panel furniture and other industries.

Nesting CNC

The nesting CNC machine is a numerical control equipment specially designed for the production of panel furniture. It is mainly used to cut various wooden boards. In terms of processing functions, the cutting machine mainly includes cutting, punching, grooving and other processes.Generally, through the design of intelligent software, nesting CNC machine can automatically optimize the typesetting design, generate the effect map, and perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheet and improve sheet utilization.

The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, This nesting CNC machine is definitely one of your indispensable CNC equipment.

Nesting CNC for Sale

Nesting CNC Router Machine for Furniture Production

1325 4x8 CNC Wood Router Bi-Zone with Multi Spindles

Edge Banding Machine

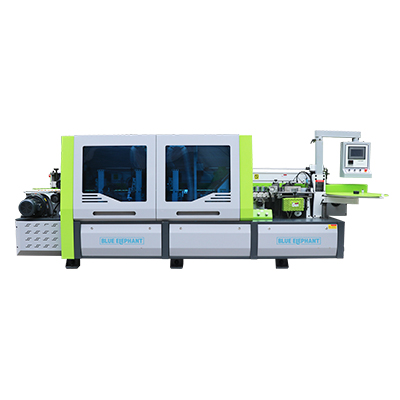

Edge banding machine is a kind of woodworking machinery, which plays the role of edge banding in the processing process of furniture production line. Compared with the traditional manual operation process, the sealing line of the edge banding machine has the advantages of straight, delicate and smooth.It has the functions of double-sided glued edge banding, cutting edge banding, compaction, flushing, chamfering, roughing, finishing, scraping and polishing. And it mainly used for edge trimming of medium density fiberboard, wood board, solid wood board, particle board, polymer door board, plywood.

Relying on the advantages of high automation, stable operation, reliability, durability, and moderate price, this edge banding machine is especially suitable for large and medium-sized furniture, cabinets and other panel furniture manufacturers. Therefore, this edge banding machine panel furniture production line is one of the important processing equipment, is also an ideal processing equipment for furniture production line. If you have similar processing needs, you can't miss this edge banding machine.

Edge Banding Machine for Sale

Fully automatic edge banding machine with pre-milling and contour tracking

Fully automatic edge banding machine with fully enclosed safety shield

Widely Used Automatic Edge Banding Wood Working Machine for Sale

Automatic Double Repair Edge Banding Machine for Panel Furniture

Subsidiary Equipment

The main production equipment of the panel furniture production line is composed of a variety of numerical control equipment such as CNC cutting machine, edge banding machine, side hole machine, laminating machine, polishing machine and so on. Each machine has its own processing function. The main function of the cutting machine is mainly to cut the board, punch, and groove.Generally, the design of various cabinets is very convenient through the design of intelligent software. The main function of the edge banding machine is to be used for edge banding after the various shaped board are cut, so that the processed sheet is more beautiful. The main function of the side hole machine is the side hole punching function after the board is cut, such as various alloy holes and wooden pin holes. After carving and cutting the cabinet door, after grinding and polishing, it can be placed in the laminating machine for vacuum lamination by spraying and drying with high-gloss films and skin-sensitive films.

These equipment have a common feature is a high degree of automation and high production efficiency. Each device cooperates with each other to meet user's individualization and diverse processing needs.

Subsidiary Equipment for Sale

Side Drilling Machine for Furniture Production

The Latest Automatic Vacuum Press Machine

Side Hole Drilling Machine for Panel Furniture

Precision Cutting Board Saw for wooden for sale