- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

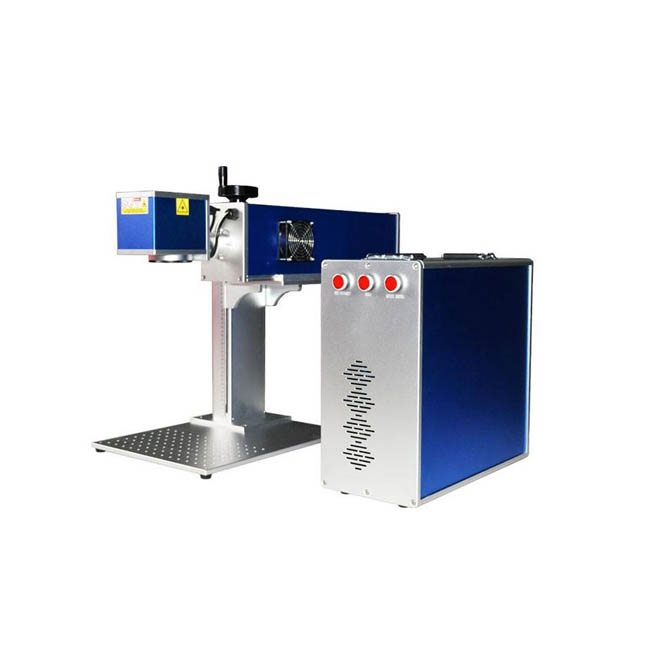

Small metal laser cutting machine

13/12/2019

Affordable Fiber Laser Cutting Machine

13/12/2019Affordable laser cutting of metal tubes and pipes

product manual

The laser cutting process replaces the traditional mechanical knife with an invisible light beam. It has the characteristics of high accuracy, fast cutting, not limited to cutting pattern restrictions, automatic typesetting to save materials, smooth cuts, and low processing costs.

It will gradually improve or replace Traditional metal cutting process equipment.

The mechanical part of the laser cutter head has no contact with the workpiece, and will not cause scratches on the surface of the workpiece during the work; the laser cutting speed is fast, the cut is smooth and flat, and generally no subsequent processing is required; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow ( (0.1mm ~ 0.3mm); no mechanical stress and no shear burrs; high processing accuracy, good repeatability, and no damage to the surface of the material; NC programming, can process any plan, can cut the entire board with large format, no need Save time by opening the mold.

Technical Parameters

| brand | style |

| model | STJ2060F |

| Laser power | 1000W(1500W,2000W,3000WOptional) |

| Laser type | fiber-optic laser |

| Cutting length | ≤6000mm |

| Cutting tube diameter | 20 mm to 220 mm |

| Repeatability | ≤±0.02mm |

| Power (power demand) | 380V / 50Hz / 60Hzof |

| price range | $ 58,800.00-$ 88,800.00 |

Features of Fiber Laser Source Laser Tube Cutting Machine:

1. The bed of the fiber laser tube cutting machine is heat treated at 600 ° C, cooled in the oven for 24 hours, the gantry is milled 8 meters, and the precise CO2 protection welding ensures that it will not deform during 20 years of use.

2. The fiber laser tube cutting machine adopts China's best brand Rex or Germany IPG fiber laser generator to obtain the best cutting quality.

3. Swiss Raytool brand laser cutting head. The optimized optical configuration makes the efficient airflow design smoother.

4. The rotary device adopts multiple automatic segment feeding methods, which is fast and accurate, and easy to clamp. It reduces the distance from the laser processing head to the tube end, reduces the waste of the material head, and improves the material utilization rate.

5. The CNC system is equipped with Cypcut software, which can meet the requirements of different pipe cutting.

6. For all types of large-diameter tolerances, fuzzy boundaries, the stepping device selectively clamps and presets the torque to ensure that the gripper is not easily deformed by the thin-walled tube

7. The air system can simultaneously acquire three different auxiliary gases and switch automatically. The high pressure air circuit is designed to improve the ability to cut stainless steel and other hard materials. The solenoid valve and proportional valve can automatically switch oxygen, nitrogen and air, and the gas pressure can be adjusted steplessly within a certain range.