- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

The best cost-effective cutting machine in 2020

06/01/2021

Economic Automatic Tool Changer CNC Router

31/12/2020Affordable multifunctional fiber laser cutting machine

Product description

Multi-purpose metal sheet and pipes fiber laser cutter is designed for cutting not only metal sheets and metal plates with different thickness, but also metal pipes and metal tubes to different shapes.

| Model | ELECNC-1325 |

| Price | Negotiation |

| X,Y,Z Working Area | 1300*2500mm |

| Laser Power | 80W/100W/150W (Option) |

| Laser type | Fiber Laser |

Advantage of Multi-Purpose Metal Sheet and Pipes fiber laser cutter

- Fiber laser cutter with tube cutting and metal sheet cutting process combination save cost and space.

- A "clean cut" surface quality is obtained.

- Reflective materials like aluminium, copper and brass can be cut with ease.

- Available for different diameter and length tubes from 20mm-200mm.

- Little to maintenance costs.

- The lifetime is over 100,000 working hours.

- Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

Features

- Equipped with the mixed laser head, it can be used to process metal and nonmetal materials.

- Designed with advance control system and driver to guarantee the stability and accuracy of machine.

- With the auto-focusing laser head, cutting and engraving depth can be adjusted automatically. So there is no need to making the second processing.

- With a wide range of applications, it widely used in advertising industry handicraft production, decoration, rubber plate furniture and other industries.

Applications of Multi-Purpose Metal Sheet and Pipes Fiber Laser Cutter

Applicable industries:Metal sheet and pipes fiber laser cutter is used in aerospace technology, aircraft manufacturing, rocket manufacturing, robot manufacturing, elevator manufacturing, ship manufacturing, sheet metal cutting, kitchen furniture, electronic components, automotive parts, cooling, ventilation pipes, signs, metal and other metal parts processing industry.

Applicable materials:Metal sheet and pipes fiber laser cutter is used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting.

Features of Multi-Purpose Metal Sheet and Pipes Fiber Laser Cutter

- High rigidity machine bed sequence welding, adopts exclusive annealing processing with high-temperature NC electric resistance furnace, ensure long-time stable working of the machine.

- Electric-drive motor in rotary device adjust speed freely. Easy-work, lower noisy, high rotary speed, high accuracy.

- Feeding system with rolls, it is easy to load heavy materials.

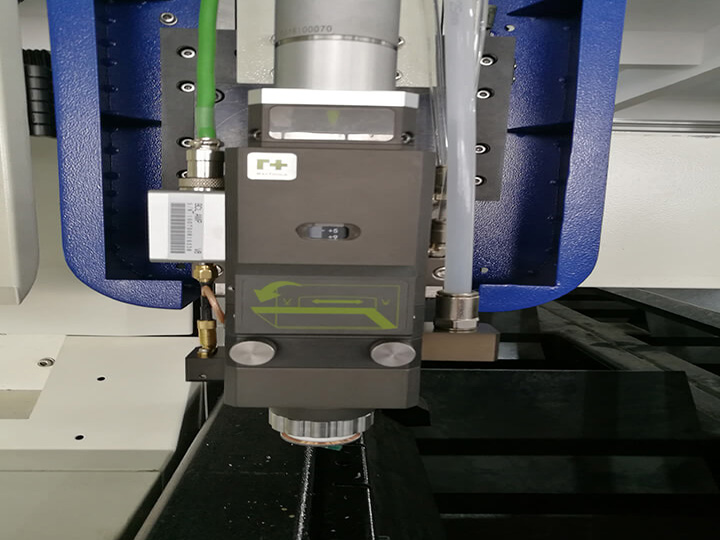

- Swiss RAYTOOLS laser head with auto focusing height follower. To ensure the constant same distance between the head and cutting material.

- Metal sheet and pipes laser cutter with Cypcut control system and software with English language. Applicable insert files with DXF or AI format. Drawing in the software is also okay. Software with fly cutting mode for cutting same products for save time. With Nesting function, autonomic compose type for saving materials by saving spaces.

- China best brand Raycus or World’s top brand IPG fiber laser source can be choose, the lifetime up to 100,000 hours.

After-Sale Service for Multi-Purpose Metal Sheet and Pipes Fiber Laser Cutter

- We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

- You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

- Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

Warranty for Multi-Purpose Metal Sheet and Pipes Fiber Laser Cutter

- 3 years for the whole machine, laser device 18 months, chiller 12 months, lens/mirror/nozzle without warranty.

- Long life-time maintenance, after-sale department will offer 24/7 English online support.

- Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

- After the warranty period expired, the buyer only need to pay the actual maintenance cost.

- Certificate support: CE, FDA, SGS.