- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

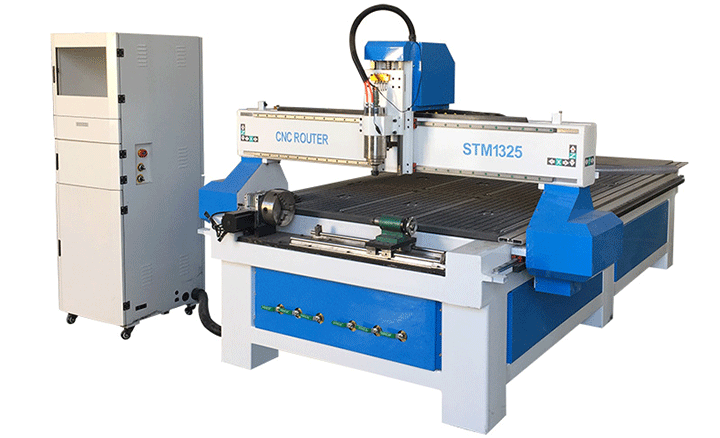

Affordable Linear ATC CNC Router with Auto Tool Changer for sale

13/01/2021

CNC milling machine

12/01/2021CNC Wood Router

Product introduction

CNC wood router is a type of wood CNC machine with Computer Numerical Controlled for smart 2D/3D cutting, carving, routing, milling, drilling and grooving on most popular woodworking, including wood crafts, wood arts, wood signs, cabinet making, wood door making, wood gifts, wood toys, wood modeling, wardrobe and other wood furniture production.

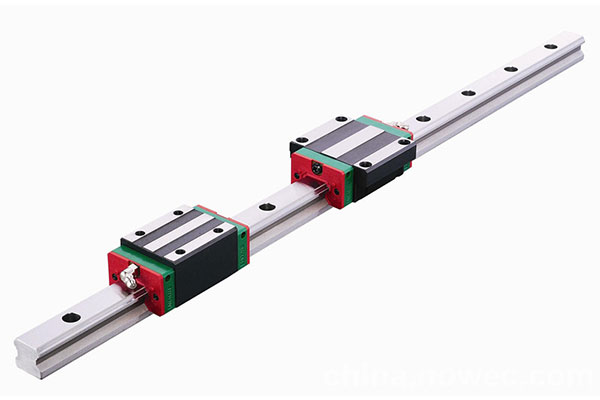

A CNC wood router is composed of CNC controller, frame, gantry, spindles, CNC operating system, CNC software, driver, motor, ball screw, guide rail, T-slot table or vacuum table, vacuum pump, power supply, limit switch, collet, rack and pinion.

A CNC wood router is also known as wood CNC machine, wood CNC router, woodworking CNC router, woodworking CNC machine, wood CNC carver, wood CNC engraver, wood CNC cutter, wood CNC table, CNC wood machine, CNC wood table, CNC wood engraver, CNC wood carver, CNC wood cutter, CNC wood routing machine, CNC wood carving machine, CNC wood cutting machine, CNC woodworking machine, CNC router for woodworking, CNC woodworking tool, computer numerical controlled wood router, computer-controlled wood router, C and C wood router.

How Many Types of Wood CNC Machine?

Types of Table: Mini/Small CNC wood router, 2x3 CNC wood router table, 2x4 CNC wood router table, 4x4 CNC wood router table, 4x6 CNC wood router table, 4x8 CNC wood router table, 5x10 CNC wood router table, 6x12 CNC wood router table.

Types of Application: Home CNC wood router machine, Benchtop/Tabletop/Desktop CNC wood router machine, 3D CNC wood router machine, Hobby CNC wood router machine, Industrial wood CNC machines.

Types of Axis: 3 axis CNC wood router, Rotary axis/4th axis CNC wood router, 4 axis CNC wood router, 5 axis CNC wood router.

What is a Wood CNC Router Used For?

CNC wood routers are widely used in industrial manufacturing, small business/small shop, home business/home shop, school education and hobbyists.

1. Furniture making: Cabinet making, door making, home doors, cabinet doors, cupboard doors, interior doors, sofa legs, table legs, spindles, screens, corners, headboards, antique furniture, art furnitures, office furnitures, wood furnitures, MDF projects, wood arts, wood crafts, composite gates, wave plate making.2. Advertising industry.

3. Die industry.

4. Hollow woodworking.

5. Relief sculpture woodworking.

6. Cylinders woodworking.

7. 3D woodworking.

8. Sign making.

Product detail drawing

How Much Does a CNC Wood Router Cost?

If you want to buy a wood CNC machine, you may wonder how much does a CNC wood router cost? how to get a final price? According to different wood CNC machine configurations, you will get the wood CNC router machine cost from $2,580.00 to $38,000.00. If you have an idea to buy a wood CNC machine overseas, the fee of customs clearance, tax, and shipping costs should be included in the final price.

Technical Parameters

| Brand | STYLECNC |

| Models | STM6090, STM1212, STM1218, STM1224, STM1325, STM1530, STM2030, STM2040, STM25120 |

| Table Sizes | 2' x 3', 2' x 4', 4' x 4', 4' x 6', 4' x 8', 5' x 10', 6' x 12' |

| Materials | Hardwood, MDF (Medium-Density Fiberboard), Plywood, Particleboard, Wood Veneer |

| Capability | 2D Machining, 2.5D Machining, 3D Machining |

| Control Software | Type3, Ucancam, Artcam, Alphacam, Cabinet Vision |

| Operating System | Mach3, Nc-studio, Syntec, DSP, Siemens, Nk200, Nk260, NK300 |

| Price Range | $2,580.00 - $38,000.00 |

How to Buy CNC Routers for Woodworking?

1. Consult:We will recommend the most suitable woodworking CNC machine to you after being informed by your requirements: The materials you want to carve and cut. The max size of the materials (Length * Width * Thickness).

2. Quotation:

We will offer you with our detail quotation according to the consulted wood CNC machine: The best specifications, accessories and affordable price.

3. Process Evaluation:

Both sides carefully evaluate the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

4. Placing Order:

If you have no doubt, we will send you the PI (Proforma Invoice), then we will sign a contract with you.

5. Production:

We will arrange the CNC wood cutting machine production as soon as receiving your contract and deposit. The latest news about production will be updated and informed to the CNC wood carving machine buyer during the production.

6. Inspection:

The whole CNC wood carving machine production procedure will be under regular inspection and strict quality control. The complete woodworking CNC machine will be tested to make sure they can work well before out of factory.

7. Delivery:

We will arrange the delivery as the terms in contract after the confirmation by the wood CNC machine buyer.

8. Custom Clearance:

We will supply and deliver all the necessary shipping documents to the CNC wood cutting machine buyer and ensure a smooth customs clearance.

9. Support and Service:

We will offer professional technical support and 24/7 free service by: Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

How to Use a CNC Router Machine for Woodworking?

1. Turn on the machine. Before starting up, it is first to determine that all connections between the CNC router machine and the computer are normal, and then turn on the power supply of the engraving machine and the computer to enter the CNC system.2. Mechanical reset. After starting the system (the system will judge whether the machine tool has "returned to the machine origin" before entering the active machining), the "return to machine origin" prompt dialog box will appear first, click the corresponding button, and the engraving machine will automatically return to the machine origin. And proofread the coordinate system.

3. Check the I/O status. Check the input and output status of each signal, check whether there is a fault signal, to ensure that the CNC router machine can process safely.

4. Manual operation.

a. Display manual operation interface. Click the [Manual] window with the mouse, a manual operation interface will appear, on this interface, you can manually operate the CNC router machine for woodworking.

b. Manually move.

Manual movement can be completed by clicking the corresponding button on the manual operation interface with the mouse. You can also manually move the wood CNC machine through the small number keys on the keyboard.

Note that you must first switch the input focus to the manual window. The detailed method is to switch to the manual window first, then click any position of the manual window with the left mouse button, and press the corresponding number key on the keyboard to complete the manual movement.

5. Set the origin of the workpiece.

The origin of X, Y, Z, A coordinates in the processing program is the workpiece origin.

Before processing, first manually move the wood CNC machine's X, Y, Z, and A axis to the orientation of the workpiece origin desired by the user, and clear the coordinate value of the current orientation in the coordinate window (or select [Operation (O )]->[Set the current point as the origin of the workpiece]), so that the current orientation is used as the origin of the workpiece for processing when the processing program is executed.