- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

Widely Used 1325 Rotary Axis CNC for Cylindrical Work Piece

16/04/2020

ELECNC-1330 4 Axis ATC CNC Router Machine for Wood Carving

16/04/2020ELECNC-2040 ATC Heavy Duty CNC Wood Machine with Rotary Device

ELECNC-2040 ATC CNC Router Machine has a front-end rotary device. This kind of rotary device saves space, usually for short-length cylinder pieces carving and engraving, such as columns, pillars, chair legs, etc. ATC spindle fetches tool from tool magazine according to your setting; 4 axis spindle dose a complex 3D wood carving better.

| Model | ELECNC-2040 |

| Price | Negotiation |

| Working size | 2060*4000*400mm |

| Control system | Taiwan SYNTEC control system |

| Spindle | Italy HSD ATC air cooling spindle |

| Motor & Driver | Japan YASKAWA servo motor anddriver |

| Table surface | T-slot and vacuum working table |

| Lubrication system | Auto Lubrication system |

| Transmission | X,Y rack and pinion drive, Z Taiwan TBI ball screw |

Features

1. Italy HSD ATC air cooling spindle and the spindle can swing 180 degrees which makes 3D wood carving better;

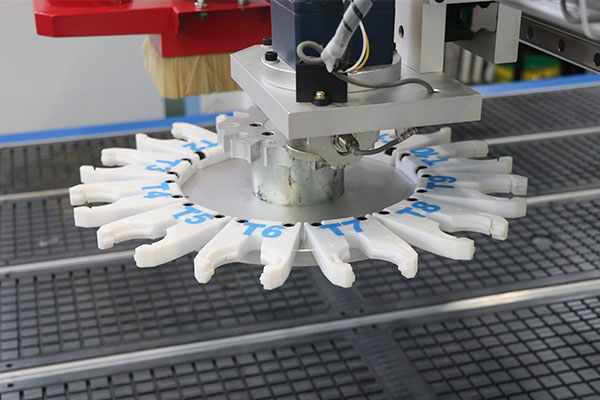

2. Carousel tool change magazine holds 12 sets of tools;

3. Front-end rotary device helps process cylindrical workpiece like Roman column, furniture legs;

4. Larger working table, it can improve the production efficiency greatly;

Detail images

Servo motor

The servo motor has the advantages of high accuracy, fast speed and long service life. In addition, it has strong anti-overload capability and can withstand a load that is three times the rated torque. When running at high speed, it has the advantages of stable operation and low noise. We provide a variety of imported brand servo motors such as Yaskawa, Panasonic, Siemens. This type of motor can not only ensure the fast and stable operation of the machine, but also ensure high precision and high quality machining results.

Computer-controlled

The computer-controlled method can not only preview the processing effect, and you can see the processing trajectory at any time, but also can correct the program loading errors during the operation in time. Each function is displayed on the control panel, which is very convenient to operate.

Linear tool magazine

The number of linear tool magazines can be customized according to the user's specific processing requirements. The position of the linear magazine can be placed under the gantry or behind the machine bed. This tool change method has the advantages of low cost and fast tool change. Especially when the linear tool magazine placed under the gantry greatly, which can save the tool changing time, improve the processing efficiency, reduce the wear on the guide rail, and prolong the service life of the machine accordingly.