- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

ELECNC-2030 3D Foam Engraving Machine

18/01/2021

4 Heads CNC Woodworking Machine for 3D Carving

15/01/2021EPS Foam Engraving Machine for Wooden Aircraft Models

Product introduction

Foam engraving machine is a kind of professional processing foam CNC equipment, belongs to the light CNC machine tool, relative to the heavy metal cutting machine tool, foam engraving machine rigidity and precision requirements are slightly lower.

Like other EPS CNC Machine, this type of foam engraving machine was designed with linear tool change magazine. Various of tools can be changed automatically in the engraving process, which means time saving.

Foam engraving machine is also called Pauline engraving machine, now there are a lot of molds are foam material, the engraving precision requirements are relatively large, in addition to the bed body is huge, so the foam engraving machine drive system multi-purpose servo drive system, Taiwan new generation or OSI control system, Italy HSD imported high power or BT series spindle.

Foam engraving machine is very different from woodworking engraving machine in the way of fixing. The material fixing of woodworking engraving machine is divided into profile fixture, vacuum adsorption, pneumatic fixture and so on.

Foam carving machine adopts steel mesa magnet fixed way, more artifacts fixed more convenient and quick, the main framework USES cold plate can be connected with the CNC bending and various special fittings, easy installation, stable movement, reasonable structure, stable performance, advanced technology, convenient operation, using this product can do to save time, save raw materials and energy saving.

Product parameter

| Model | ELECNC-1530 |

| Price | Negotiation |

| X,Y,Z Working Area | 1500x3000x1100mm |

| Control system | Taiwan SYNTEC control system |

Foam Engraving Machine Features

1. With a true four-axis, and the machine’s spindle can swing 180 degree to do three-dimensional processing.

2. EPS Styrofoam CNC Machines has been widely applied for processing EPS, casting wood mold, and other non-metal material mold.

3. The Z axis can be heightened, and the whole working size also can be customized.

4. Designed with linear tool change magazine, it can improve working efficiency.

Manufacturing Process

High-power CNC stereo foam engraving machine requires that the body must be precise and stable, so long-term high-power engraving should use the casting body to ensure its processing accuracy and stability.

Foam Engraving Machine Detail images

Servo motor

The servo motor has the advantages of high accuracy, fast speed and long service life. In addition, it has strong anti-overload capability and can withstand a load that is three times the rated torque. When running at high speed, it has the advantages of stable operation and low noise. We provide a variety of imported brand servo motors such as Yaskawa, Panasonic, Siemens. This type of motor can not only ensure the fast and stable operation of the machine, but also ensure high precision and high quality machining results.

Water cooling spindle

This type of spindle adopts water circulation to cool the heat generated after the spindle rotates at high speed, which has the advantages of good cooling effect, low noise, long service life and high accuracy. We can provide a variety of brands at home and abroad for customers to choose from, to meet the diverse processing needs of users.

Computer-controlled

The computer-controlled method can not only preview the processing effect, and you can see the processing trajectory at any time, but also can correct the program loading errors during the operation in time. Each function is displayed on the control panel, which is very convenient to operate.

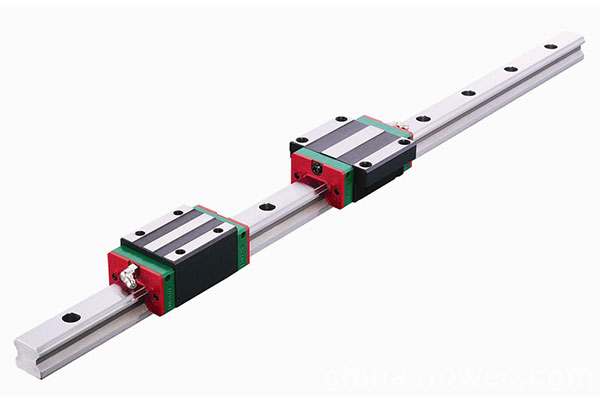

Square rail

With the advantages of strong load capacity and accuracy maintaining ability, stable operation, low friction resistance, high positioning accuracy, and good reproduction.The square rail not only guarantees the high-speed and high-quality operation of the engraving machine, but also maintains high precision for a long time. So it is suitable for large format fine carving, and it is ideal for stone engraving machines, woodworking engraving machines, foam engraving machines, etc.

Apply to industry

Furniture decoration, stone industry, wooden handicraft industry, large area plate plane carving, solid wood furniture, solid wood art murals, density board paint-free doors, composite doors, cabinets, Windows, bedside tables, screen carving, etc.

Mold industry: can engraving all kinds of molds, wood molds, aviation wood molds, propellers, automobile foam molds and other non-metal.<

The development direction

CNC processing of foam model required by solid casting has the obvious advantages of uniform and accurate allowance and good overall appearance effect of the mold. The important machined parts of the machine have gone through annealing and other heat treatment processes. After processing, CMM is carried out to ensure the accuracy of parts and components.

The full programmed processing of foam engraving machine will be the direction of future development, of course, there are many technical problems in this field need us to further explore and study.

Product guarantee

1. National patented products and hundreds of users.2, Adopt high-quality accessories, powerful function, simple operation, highly humanized.

3, Provide a full set of solutions: including modeling design, programming, tooling design, tool selection, processing data, machine training.