- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

Large Gantry 5 Axis CNC Machine for Sale at Cost Price

21/01/2021

5 Axis CNC Router for Sale at Affordable Price

20/01/2021Industrial 5 Axis CNC Router Machine for 3D Milling and Carving

Industrial 5 Axis CNC router Machine Applications

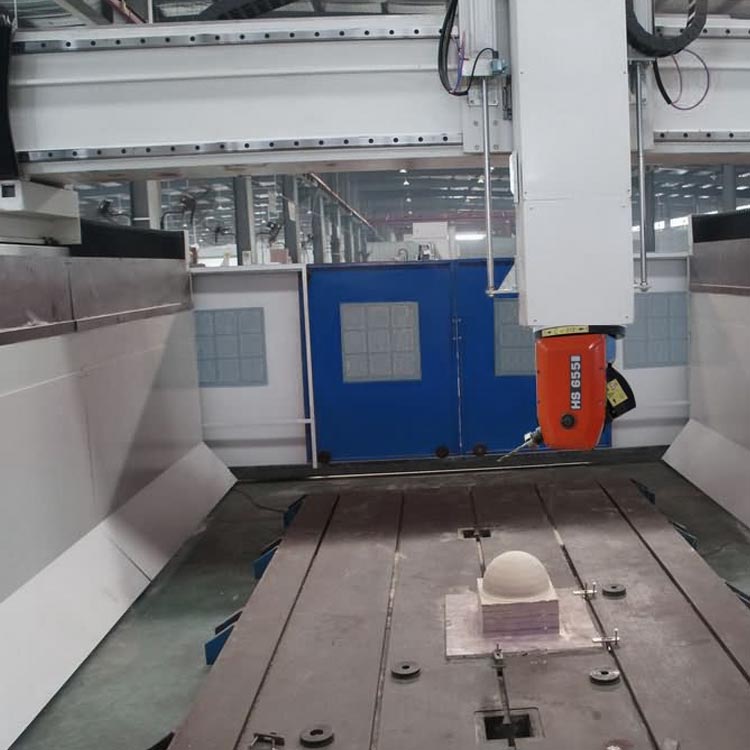

STM2040 5 axis series is a powerful high performance production machine for large format 5 axis CNC machining. It comes as standard with a 12kw HSD spindle, Yaskawa digital closed servo transmission, helical rack and pinion with a moving gantry design. It also has the option of a precision machined cast steel T-Slot work table for accurate fixturing of large moulds. The 5 axis CNC machine is used extensively in the mold making, boat building/marine and pattern making industry.

Mold industries: sculpture, large non-metallic mold, car lost foam pattern, wooden ship model, wooden model aviation and other wood mold.

Non-ferrous metals: aluminum, copper, alloys and other ligh non-ferrous metal processing.

Industrial 5 Axis CNC Router Machine Technical Parameters

| Model | STM2040-5A | |

| Movement type | Moving gantry | |

| X working area (MM) | 2000 | |

| Y working area (MM) | 4000 | |

| Z working area (MM) | 1100 | |

| C travelling | ±213° | |

| A travelling | ±112° | |

| Double pendulum head | 12KW Liquid cooled HSD | |

| Range of speeds | 22000 RPM | |

| Servo Motor brand | YASKAWA | |

| Table size (MM) | 2000 x 4000 | |

| Product fixed form | Optional Cast Steel Work table with T-Slots | |

| Tool magazine | Linear tool rack (8 positions) | |

| Control system | Syntec | |

| Machine size | 7000 x 6300 x 4600mm | |

| Total weight | 22000Kg | |

| Total Power(kw) | 24KW | |

| Voltage | AC415V/50HZ | |

| Data Transmission | RJ45 – USB | |

| File exchange | G code | |

| Maximum speed | X Axis | 40m/min |

| Y Axis | 40m/min | |

| Z Axis | 40m/min | |

| C Axis | 40m/min | |

| A Axis | 40m/min | |

| Guarantee time | 12 months | |

| Option items: | 250m3/hr vacuum pump | |

| Alphacam or Delcam software | ||

Industrial 5 Axis CNC Router Machine Standard Configurations

1. The five axis CNC router machine is equipped with high quality four-row ball bearing, wide linear lead rail and self-lubricating block for the machine. It can balance the force in all directions to ensure the machine’s accuracy and strength when machining.

2. Z axis can be heightened to 900mm, so it is suitable for processing large-scale and super-thick material.

3. The design documents of intelligent processing cross-border protection can prevent the excessive process caused by mechanical impact.

4. The diversified processing speed can be controlled separately. The speed of idle running and roll setting improve the quality of processed products and processing efficiency greatly.

5. Travelling area for STM2040 5 axis machine: 3000 x 4800 x 1500mm.

6. Extra heavy duty welded steel frame and gantry for maximum straightness and rigidity.

7. 12KW HSD liquid cooled spindle.

8. 8 position linear ATC with HSK63F precision tool clamping.

9. THK lubricated for life linear rails and guide blocks.

10. Yaskawa digital servo drivers and motors for high power, accuracy and speed.

11. Syntec – PC interfaced Numerical Control System.

12. Automatic machine lubrication system (option).

13. MPG XYZAC Hand Wheel for easy origin and work piece setting.

14. Tool setting device.

15. One starter set woodworking tools.

16. 3 x collets, choice from 1-20mm (imperial available if preferred).

17. 1 x HSK 63F Tool Holder included.

18. Inverter: Taiwanese Delta Inverter 0-22000rpm control.

19. German Schneider Electronic spare parts.

20. Japanese OMRON limit switches.

21. MAXICAM double sheathed, fire retardant and highly flexible towline cable can be bent 300,000 times.

22. Igus cable chain carrying system.

23. Voltage: 3PH 415V 50HZ.