- A Guaranteed CNC Machine Manufacturer and Supplier

- 0086-531-88621860

Linear Automatic Tool Changer CNC Router Machine with 5×10 Table Size

28/12/2020

Detailed explanation of CO2 laser cutting machine for small enterprises

23/12/2020Introducing CO2 laser cutting machine

Product description

CO2 laser cutting machine is a CNC laser cutting machine, which uses CO2 laser to cut wood, MDF, plywood, chipboard, cardboard, cardboard, acrylic, fabric, jeans, plastic, leather, paper, ABS, EPM, PE, PES , PUR, PVB, PVC, PUR, PMMA, PTFE and thin metals are widely used in industrial manufacturing applications, school education, small businesses, home businesses, small shops and home stores.

The CO2 laser beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical CO2 laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye.

How Does a CO2 Laser Cutter Work?

The CO2 laser beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical CO2 laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye.

The CO2 laser beam is only about 3/4 of an inch in diameter as it travels from the laser resonator, which creates the beam, through the machine’s beam path. It may be bounced in different directions by a number of mirrors, or “beam benders”, before it is finally focused onto the plate.

The focused CO2 laser beam goes through the bore of a nozzle right before it hits the plate. Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen.

CO2 Laser Engraving Cutting Machine Features

1. With a precision water cooling CO2 laser generator, it can process various non-metallic materials and processing of some metal materials.2. With the international imported component, it makes the machine have a higher machine accuracy.

3. Equipped with the rotary device, it can be used to process any cylindrical object, such as cup, brush pot, musical instrument and so on.

4. This machine can be compatible with WIN7, Vista, XP and WIN2000.

Product parameter

| Model | ELECNC-1390 |

| Price | Negotiation |

| Processing area | 1300mm*900mm |

| Laser power | RECI 130-150W |

| Laser type | Sealed Co2 glass laser tube |

| Cooling | CW5200Water cooling |

Detail images

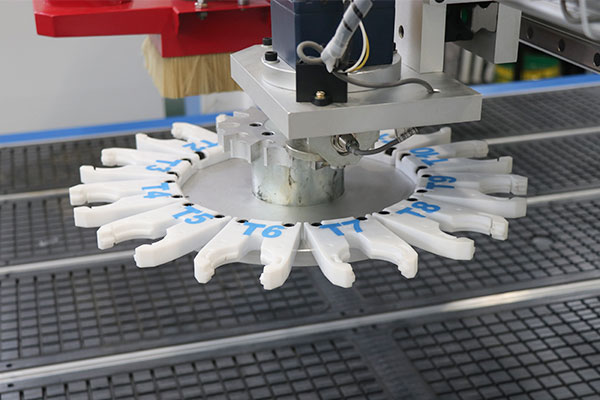

Carousel tool magazine

The number of tools in the carousel magazine can be customized according to the user's processing requirements. The tool magazine can be placed next to the spindle or on the side of the gantry.

This carousel tool change method has the feature of faster tool change speed, so the production efficiency is higher. In addition, this tool change method make the machine run more stably, which can ensure higher machining accuracy and higher processing quality.

Tube Welded Bed

With the features of high strength, not easily deformed, it can ensure that the bed will not be deformed for 20 years like high strength, good stability and strong tensile strength. Moreover, the rectangular tube has a wall thickness of 10 mm and the entire body weighs 4,500 kg, it makes the machine run stably.

How to Buy a CO2 Laser Cutter?

1. Consult:We will recommend the most suitable CO2 laser cutting machine to you after being informed by your requirements.

2. Quotation:

We will offer you with our detail quotation according to the consulted machine.

3. Process Evaluation:

Both sides carefully evaluate and discuss all the details (technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

4. Place an order:

If you have no doubt, we will send you a PI (Proforma Invoice), and then we will sign a contract with you.

5. Production:

We will arrange the production of the laser machine immediately after receiving your sales contract and deposit. The latest news about production will be updated during the production process and the buyer will be notified.

6. Quality control:

The entire production process of the CO2 laser machine will be subject to regular inspections and strict quality control. The whole set of machines will be tested to ensure that they can work normally before leaving the factory.

7. Delivery:

After the buyer confirms, we will arrange delivery according to the terms in the contract.

8. Customs clearance:

We will provide all necessary shipping documents and deliver them to the buyer and ensure smooth customs clearance. 9. Support and service:

We will provide professional technical support and free services via telephone, email, Skype, WhatsApp, online real-time chat, and 24/7 remote service. We also provide door-to-door service in some areas.