ELECNC 2030 Linear ATC CNC router with EOT-3 Oscillating Knife

6*10 ATC CNC router with EOT-3 Oscillating Knife cutter, the function of CNC router and cutter is independent, ATC makes woodworking automatically, help the man out of the manual operation of choosing and fixing tool/bits, also greatly saves much time. EOT-3 Oscillating Knife cutter meets the cutting needs of Leather, Carpet, Carton, Cardboard, Rubber, etc.

| Model | ELECNC-2030 |

| Price | Negotiation |

|

| Working area | 2000*3000*500mm |

| Spindle | 5.5kw CS ATC water cooling spindle |

| Inverter | 5.5kw Fuling inverter |

| Tool magazine | 8 linear tool magazines with BT 30 tool holder |

| Motor and driver | 850w Leadshine servo motor and driver |

| Oscillating knife | Germany EOT-3 oscillating knife |

| Working Table | Full absorption vacuum table |

Features

1. German EOT-3 oscillating knives cut soft materials such as leather, carton, and cloth as well as ordinary materials like wood, MDF,

acrylic, etc.

2. Linear auto tool changer with 8 tool magazines, cost-effective for automatic woodworking

. 3. Vacuum table with stronger adsorption force, for a better fix of material.

4. A high-performance drive motor ensures high speed and accuracy.

Servo motor

The servo motor has the advantages of high accuracy, fast speed and long service life. In addition, it has strong anti-overload capability and can withstand a load that is three times the rated torque. When running at high speed, it has the advantages of stable operation and low noise. We provide a variety of imported brand servo motors such as Yaskawa, Panasonic, Siemens. This type of motor can not only ensure the fast and stable operation of the machine, but also ensure high precision and high quality machining results.

Computer-controlled

The computer-controlled method can not only preview the processing effect, and you can see the processing trajectory at any time, but also can correct the program loading errors during the operation in time. Each function is displayed on the control panel, which is very convenient to operate.

Linear tool magazine

The number of linear tool magazines can be customized according to the user's specific processing requirements. The position of the linear magazine can be placed under the gantry or behind the machine bed. This tool change method has the advantages of low cost and fast tool change. Especially when the linear tool magazine placed under the gantry greatly, which can save the tool changing time, improve the processing efficiency, reduce the wear on the guide rail, and prolong the service life of the machine accordingly.

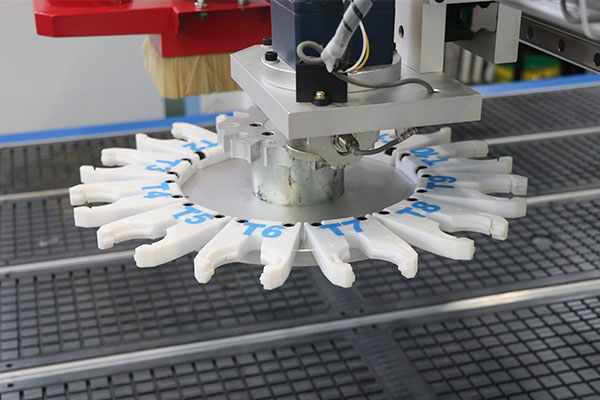

Carousel tool magazine

The number of tools in the carousel magazine can be customized according to the user's processing requirements. The tool magazine can be placed next to the spindle or on the side of the gantry. This carousel tool change method has the feature of faster tool change speed, so the production efficiency is higher. In addition, this tool change method make the machine run more stably, which can ensure higher machining accuracy and higher processing quality.